Available Building Blocks

We are the world leader in catalyst production equipment. Our pride is based on specially designed systems that are used by more than 100 machines worldwide.

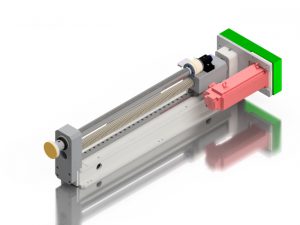

Laser Measuring

Kirschenhofer has developed 2 measuring machines to cover the requirements of substrates for cars and trucks.

Kirschenhofer has developed 2 measuring machines to cover the requirements of substrates for cars and trucks.

The device measures the circumference of the substrate and determines if it complies with the specification.

The same measuring machines are used to measure the finished part to determine the gap bulk density (GBD).

Measuring Software

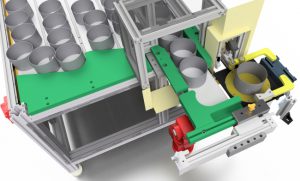

Mat Station

Kirschenhofer supplies mat weighing stations with manual loading, automatic loading from packaging or loading from buffer.

The station is equipped with an automatic wrapping function. Automation of this process allows for faster and more accurate results.

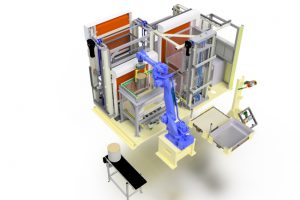

Pushin Station

The stuffing station is equipped with a force measuring system to ensure that the mat is not damaged during the insertion process.

The station also has the Kirschenhofer patented variable insert cone.

Tube processing

Kirschenhofer supplies tube processing stations for pre- and post-sizing. The number of processing steps is freely configurable by the customer.

Kirschenhofer supplies tube processing stations for pre- and post-sizing. The number of processing steps is freely configurable by the customer.

Engraver station

Engraver stations are used to scribe,pin-stamp or laser identification information on the tube. It consists of one or two engravers, which are automatically loaded and unloaded with a high-speed handling system.

The station can be equipped with needle printers or laser engravers.

Automated Infeed

Kirschenhofer offers the automatic feeding of substrates from belts or directly from the packaging.

Tube feed is offered via surface storage, or directly from grid boxes. Mat feed directly from the packaging or from mat buffers.

Automatic removal

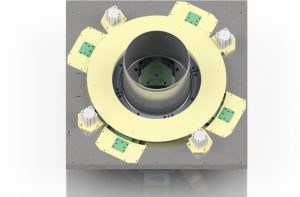

Special Purpose Stations

Kirschenhofer developed a diverse range of stations for autonomous machines to determine product quality.

Non-contact tube thickness measurement, mats position control, pushing force measurement, substrate breakage detection, etc.

-

1998

- Development of the first converter canning machine

- Gap Calibration

- MML1 measuring machines with belts

- Expander with servo technology

-

2000

- Canning machine for non-round substrates

- First semi-automatic canning machine

- MML2 - the first measuring machines with laser technology

-

2002

- Canning machine for Substate with hole

- Tube forming station for punching tubes

-

2004

- Development of a semi-automatic machine for truck converters

- Development of a tourniquet machine for round and non-round substrates

-

2006

- Development of a GBD-calibrated machine

- Development of first servo driven shrinker

- MML3-new laser measuring machine development with an accuracy of 0.05mm

-

2008

- Development of automatic substrate and mat wrapping

- MML3 extension for GBD post measurement

- Automatic machine for truck catalyst production

-

2010

- First steps to autonomous machines with the development of:

- Mat infeed with buffer

- Pipe infeed with buffer

- Development of Servoshrinker for trucks

- First steps to autonomous machines with the development of:

-

2012

- Processing of 3 substrates

- Development of a new endform tool

- Automatic tube trimming machine

-

2014

- Automatic stacking of finished parts onto trolleys

- Development of a new mat scale

- Upgrade of MML for higher accuracy of 0.02 mm

-

2016

- Autonomousmachine

- Feed substrates from packaging automatically

- Control of substrate edges after damage

- MML Advance - Measuring with best fit GBD

- Autonomousmachine

-

2017

- Development of tube thickness measuring

- Development of a mat position control

- Endurance test for new shrinker with variable number of jaws

- Automatic feeding of the tubes from grid boxes